How are Monocase Air made?

The Challenge of Going Ultra Thin

Creating a phone case that’s just 0.35mm thin — thinner than a credit card — is no easy feat. It’s not just about scaling things down. It’s about precision, material mastery, and a refusal to compromise on quality, fit, or durability.

Our Material: Luxury TPU

At the heart of MonoCase Air is Luxury TPU, a premium-grade thermoplastic polyurethane. Unlike ordinary TPU, this version is specifically selected for its clarity, flexibility, and structural strength — all while maintaining an ultra-slim profile. It resists yellowing, warping, and distortion, even at extremely thin dimensions.

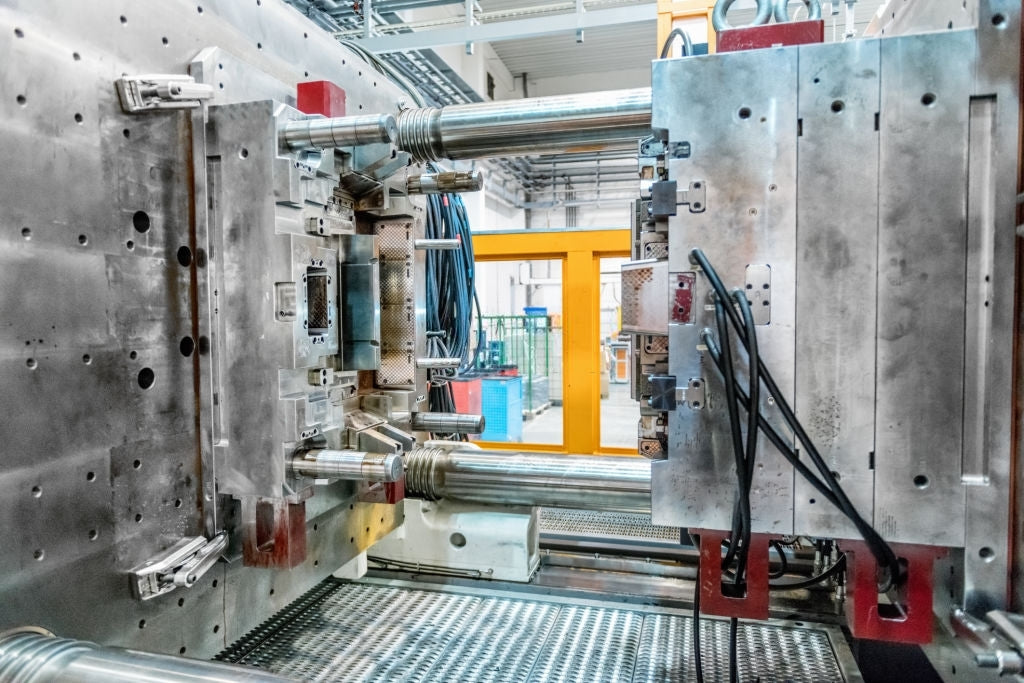

Precision Moulding Process

We begin by creating custom CNC-machined moulds, engineered with micron-level accuracy. These moulds are tailored to each phone model, ensuring that every curve, button, and port is perfectly aligned. With tolerances this tight, even the slightest deviation could ruin a case — so we don’t take shortcuts.

Careful Resin Shaping

The Luxury TPU is injected into the mould, then pressed and shaped with extreme control over timing and temperature. Because the material is so thin, it cools rapidly — meaning every second counts. Standard machinery simply can’t manage this alone, which is why trained technicians step in to assist where machines fall short.

Hand-Finished for Perfection

Once moulded, every case undergoes a careful inspection. Overhangs and seams from the moulding process are trimmed by hand, ensuring each case has the smooth, flawless edges you expect from a premium product. These final touches are what make MonoCase Air feel as good as it looks.